If you’ve ever looked at a cottage window and thought “that’s exactly what I want” — you’re probably thinking of a flush casement.

There’s something about that clean, traditional aesthetic that just works. The sash sits level with the frame, creating smooth, uninterrupted lines that have graced British homes for centuries. No projecting edges, no bulky profiles — just elegant simplicity.

But flush casements aren’t just about looks. They’re a practical choice for conservation areas and period properties where authenticity matters. Understanding what they are and where they came from will help you decide if they’re right for your home.

What You’ll Discover in This Article

- What makes a casement window ‘flush’ versus ‘stormproof’

- The historical context behind flush casement design

- Modern weather sealing and drainage technology

- Style variations: glazing bars, hardware, finishes

- When flush casements are (and aren’t) the right choice

What Makes a Casement ‘Flush’?

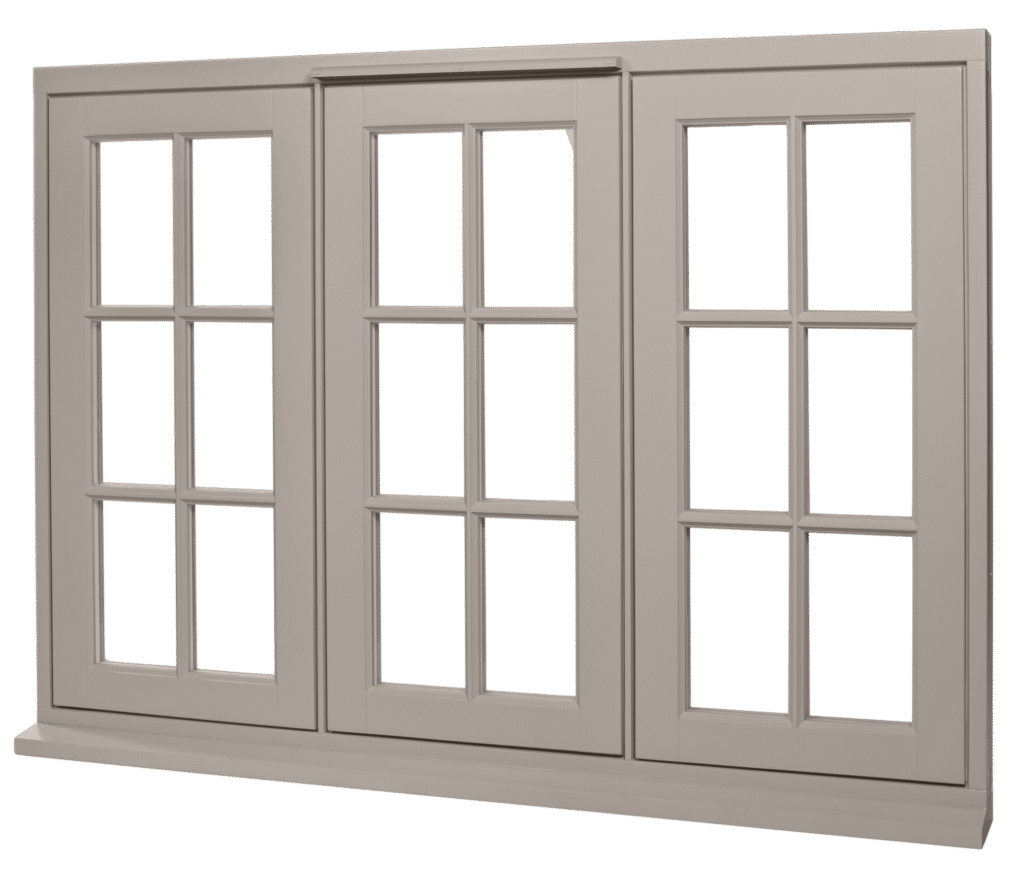

The distinction is simpler than you might think. When a flush casement closes, the opening sash sits level with the outer frame — flush, in other words. Compare this to ‘stormproof’ designs where the sash projects forward, overlapping the frame.

Stand outside and look at a stormproof casement — you’ll see the sash sitting proud of the frame, creating shadows and visual depth. Now look at a flush casement — the whole window appears as a single, flat plane. It’s a subtle difference that dramatically affects the overall aesthetic.

This flat profile is why flush casements suit traditional architecture so well. They were the original casement design, used for centuries before stormproof styles emerged. When you fit flush casements to a period property, you’re restoring something closer to the building’s original appearance.

A Brief History of Flush Casements

Before the Victorian era, virtually all casement windows were flush. The technology to reliably weatherproof a projecting sash simply didn’t exist. Carpenters fitted casements that closed flat against their frames, sealed with putty or linseed oil compounds.

Georgian, Regency, and early Victorian properties featured flush casements (or sliding sashes). Walk through any historic village and you’ll see them everywhere — grand manor houses to workers’ cottages.

The late Victorian period saw stormproof casements emerge. By overlapping the frame, these designs offered better weather resistance. Combined with improved hardware, they became dominant through the 20th century.

Modern manufacturing has solved the precision problem. CNC machinery achieves tolerances Victorian craftsmen couldn’t match. Contemporary weatherstripping means flush casements can equal stormproof performance while looking authentically traditional. We’re manufacturing more now than at any point in 50 years.

Technical Considerations

Let’s address the elephant in the room: weather performance. Historically, flush casements had a reputation for being less weather-resistant. That reputation was deserved — once.

Modern sealing: Today’s flush casements use sophisticated multi-point weatherstripping. Compression seals around the entire perimeter create effective barriers against wind and rain. Properly specified, they achieve the same weather ratings as projecting designs.

Drainage: Quality flush casements incorporate discrete drainage channels directing water away from seals. You won’t see them from outside — they’re hidden within the profile — but they’re essential for long-term performance.

The quality factor: Flush casements are less forgiving of poor manufacturing or installation. Seals must contact precisely around the full perimeter. This is why quality matters even more with flush designs — cheap versions fail where stormproof might survive.

Style Variations and Options

Opening configurations: Most flush casements are side-hung. Top-hung variants work well for ventilation, particularly in kitchens. Some designs combine both — a top-hung fanlight above a side-hung main sash.

Glazing bars: These divide windows into smaller panes — either genuinely (separate glass pieces) or visually (applied bars over single units). Traditional cottages featured six, eight, or twelve panes per sash. True divided lights are more authentic but reduce thermal performance; applied bars maintain a clean glazed surface.

Hardware: Traditional casement stays and cockspur handles capture period aesthetics while modern reproductions incorporate contemporary security. Friction hinges allow windows to hold at any angle — practical, though less traditionally authentic.

Dual-colour finishing: Match external colours to conservation requirements while keeping neutral interiors. Especially useful when specific external colours are required that wouldn’t suit interior décor.

Where Flush Casements Excel

Flush casements aren’t the right choice for every property. But when they’re right, they’re the perfect choice.

Conservation areas: Often required by planning conditions. Flush casements satisfy planners while delivering modern performance.

Period cottages and farmhouses: The traditional aesthetic matches architectural character. Stormproof windows look incongruous on these properties.

Arts and Crafts architecture: Clean lines suit the honest, handcrafted aesthetic. Many original Arts and Crafts houses featured flush casements.

Modern builds seeking traditional aesthetics: Even new construction can benefit when cottage-style appearance is desired.

Frequently Asked Questions

FAQ

Can I get flush casements with triple glazing?

–

+

Yes, though the deeper glazing unit requires modified frame profiles. Some traditional-looking designs can accommodate 32mm triple-glazed units while maintaining authentic proportions. Discuss specific U-value requirements with your manufacturer — compromises may be needed for very slim sightlines.

What’s the price difference between flush and stormproof casements?

–

+

At Wooden Windows Online, flush and stormproof casements are priced identically. We believe the choice should be about aesthetics and suitability for your property, not budget constraints. Both styles receive the same quality materials and manufacturing precision.

Will conservation officers always require flush casements?

–

+

Not automatically. Requirements vary by local authority and individual property. Some accept stormproof for non-principal elevations or replacement of existing stormproof windows. Always check with your local conservation officer before ordering — pre-application advice prevents expensive mistakes.

How do I maintain flush casement windows?

–

+

Same as any timber window: inspect paintwork annually, repaint every 5-8 years depending on exposure, keep drainage channels clear, lubricate hardware annually. Pay particular attention to the seal contact areas — any damage allows water ingress. With proper maintenance, expect 50-60+ years of service.

Conclusion

Flush casement windows combine timeless elegance with modern performance. They’re not trying to look like traditional windows — they are traditional windows, manufactured with contemporary precision.

For conservation areas, period properties, and homes where traditional aesthetics matter, they’re an obvious choice. For contemporary buildings or very exposed locations, stormproof designs might make more sense.

Not sure which suits your property? Get in touch for a free consultation — we’ll help you find the right solution.

Our Best-Selling Timber Windows: