Craftsmanship and Heritage: The Timeless Appeal of Handmade Wooden Windows

What You’ll Discover in This Article:

- Why handmade timber windows offer superior quality and character compared to mass-produced alternatives

- How traditional joinery techniques like mortise and tenon joints ensure exceptional durability and longevity

- The perfect fusion of time-honoured craftsmanship with modern precision manufacturing

- What separates truly bespoke wooden windows from standard factory products

- Why investing in handmade wooden windows adds lasting value and heritage to your home

Introduction

Run your hand along a piece of handmade furniture. Feel that? The smooth finish, the precise joints, the way everything just feels right. Your windows should give you that same feeling.

In an era where most products barely make it to their tenth birthday, handmade timber windows are different. Properly maintained Victorian sash windows still work perfectly after 150 years. Modern replacements? Many struggle past 20. The difference isn’t just the materials—it’s the craftsmanship.

Recent surveys show UK homeowners are increasingly seeking products with provenance and longevity, particularly for period properties and heritage homes. There’s a reason those original Georgian windows endure whilst their “modern improvements” from the 1980s are already falling apart.

This guide explores what truly makes a window “handmade” in today’s world, why traditional joinery techniques remain superior, and how you can recognise genuine quality when choosing timber windows for your home. Whether you’re restoring a listed building in Chelsea or renovating a Victorian terrace in Manchester, understanding craftsmanship makes all the difference.

Handmade Timber Windows: Quality Begins with Material Selection

Before a single cut is made or joint assembled, the journey of a quality handmade timber window begins in the forest. Not just any timber will do. The selection process is where true craftsmanship first reveals itself.

A timber merchant I worked with once told me he can judge a workshop’s quality just by watching them select wood. “The good ones take their time,” he said. “The cowboys grab whatever’s closest.”

He’s right. Skilled craftsmen don’t just order wood by the cubic metre. They understand that European oak behaves differently to engineered pine, that meranti has its own characteristics. Growth rings tell them how the tree grew—and more importantly, how the wood will move over decades. Tight, even rings? That’s slow growth. That’s stable timber. Wide, irregular rings? That wood will cause you problems in year five, year ten.

When craftsmen select timber for bespoke windows, they’re looking for stability above all else. They check for knots, splits, or irregularities that might compromise the window’s integrity thirty years down the line. This knowledge takes years to develop—the kind passed down through apprenticeships, not PowerPoint presentations.

Here’s what catches people by surprise: modern handmade doesn’t mean rejecting technology. Today’s finest window makers often use engineered timber for core structures. This isn’t a compromise—it’s an improvement. Engineered timber takes carefully selected wood and enhances its stability, reducing the natural movement that causes traditional windows to stick or warp. The craftsman’s skill lies in knowing which pieces to use where, how to orient the grain for maximum strength, and how to combine materials for the best possible outcome.

Think of a chef selecting ingredients. They wouldn’t use whatever’s available. Neither should your window maker. Starting with exceptional raw materials—and understanding their properties—is half the battle won.

Traditional Joinery Meets Modern Precision: The Craftsmanship Behind Wooden Windows

There’s a common misconception about handmade wooden windows: that “handmade” means a craftsman in a dusty workshop using only hand tools from centuries ago. The reality is more interesting.

Modern handmade timber windows represent a marriage between traditional knowledge and contemporary precision. A skilled craftsman today has access to CNC machinery that cuts timber to tolerances within 0.2mm. But here’s the crucial difference: they’re operating that machinery, making decisions about grain direction, adjusting for the wood’s individual characteristics, and inspecting every piece with experienced eyes. It’s not a robot mindlessly repeating operations—it’s a craftsperson using the best available tools.

Where handmade craftsmanship truly shines is in the joinery. This is where generations of knowledge become invaluable.

The mortise and tenon joint dates back thousands of years. It’s still the gold standard. Why? Because it works.

I once watched a restoration team carefully dismantle a Georgian window from 1823. The mortise and tenon joints showed almost no wear after 200 years. The screws from a 1970s “improvement”? Corroded through in 30.

A properly cut mortise and tenon, glued and assembled by skilled hands, is actually stronger than the wood around it. The joint distributes stress naturally. It can be repaired centuries later. Compare this to mass-produced windows, where components are simply screwed or stapled together. Those mechanical fixings work initially, but they rely on holding power that diminishes over time. Wood around screws compresses. Metal corrodes. Joints loosen.

A traditional mortise and tenon can actually improve with age as the wood settles and the joint tightens.

Modern craftsmen also understand when to use dowels, biscuits, or modern adhesives to complement traditional joints. They know how to reinforce stress points without compromising the window’s aesthetic or its ability to be repaired in future. This isn’t about being a purist—it’s about using every available advantage to create a window that outlasts its owner.

The technical expertise extends to glazing as well. Installing double glazed wooden windows properly requires understanding thermal expansion, moisture management, and how different sealants perform over decades. A craftsman doesn’t just drop glass into a rebate—they consider how the window will perform through fifty winters and summers.

Bespoke Timber Window Quality: Precision Details That Define Excellence

Stand close to a handmade timber window and you’ll notice something subtle: perfection in the details. The margins between frame and sash are consistent. The mouldings align seamlessly. The finish is smooth to the touch, without runs, sags, or missed spots. These aren’t happy accidents—they’re visible signs of genuine craftsmanship.

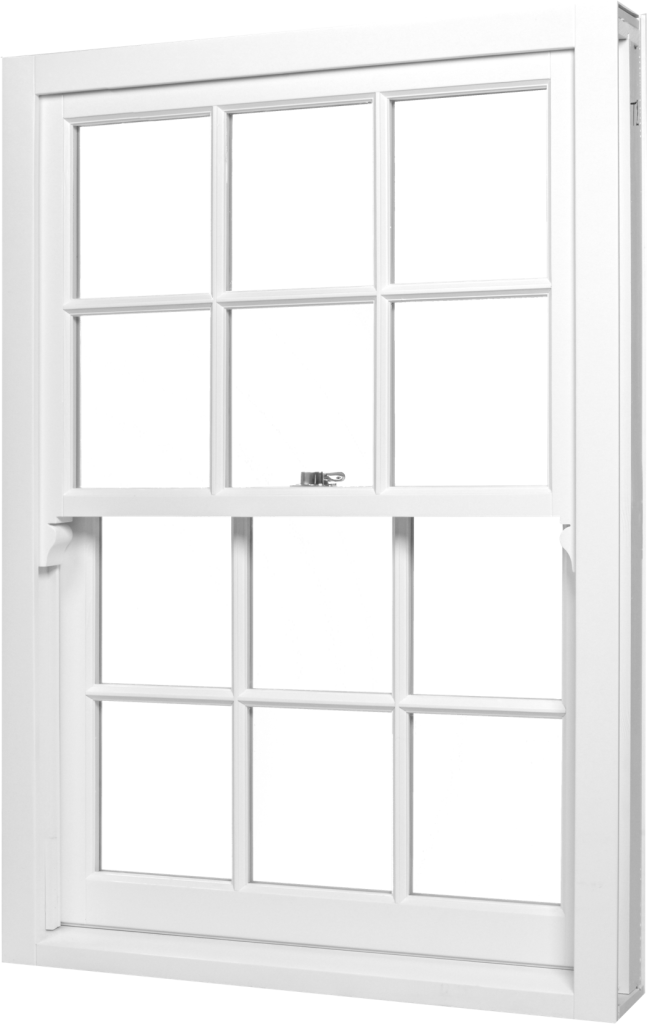

Want a quick quality test? Close your sash window and try to slide a piece of paper between the frame and meeting rails. On a properly made window, you won’t manage it. On a cheap one? You’ll fit your finger through the gap. That’s the difference precision makes.

Or try this: open your window halfway. Does it stay put, or does it creep down? A well-balanced window—whether using traditional weights or modern spring systems—should hold position at any point. No fighting, no sticking, no feeling like you’re wrestling with the thing.

Quality reveals itself in smooth operation. A properly made sash window should glide open with about 2kg of effort, balanced perfectly at any position. This level of precision requires hand-fitting—testing, adjusting, and fine-tuning until everything works as it should.

The finish is perhaps where you’ll most clearly see the difference between handmade and mass-produced. A microporous finish system isn’t just slapped on—it’s carefully applied in 3-4 thin coats, each one allowed to cure properly before the next. The craftsman pays attention to end grain, joints, and hard-to-reach areas that a spray booth might miss. They understand that quality finish isn’t just about appearance; it’s the window’s first line of defence against British weather.

This attention extends to the hardware as well. Quality Georgian windows feature carefully selected ironmongery that’s not just decorative but functional. Hinges are positioned for optimal weight distribution. Locks engage smoothly and securely. Even the choice of screws matters—stainless steel in vulnerable areas, brass where tradition demands it.

What you’re seeing in these details is something that simply can’t be rushed. Mass production works on the principle of “good enough”—meeting minimum specifications quickly and cheaply. Handmade craftsmanship operates on the principle of “as good as it can possibly be.” There’s no time clock pushing the work along, no target for how many windows must be completed per shift. The window is finished when it meets the craftsman’s standards, not the production manager’s schedule.

This difference becomes even more apparent over time. A well-made window ages gracefully. Joints remain tight. Finish weathers evenly. When maintenance is needed, it’s straightforward—sand, recoat, adjust. You’re not dealing with failed sealed units, delaminating vinyl, or corroded aluminium. You’re simply maintaining a quality product that was built to be maintained.

Heritage Wooden Windows: A Long-Term Investment in Your Property

Let’s be honest about cost. Quality timber windows aren’t cheap. You might pay £800-1,200 per window versus £400-600 for basic modern alternatives. That’s double the upfront investment.

But here’s the arithmetic: if those handmade windows last 60+ years (which they will with basic maintenance), while the cheaper options need replacing at 20 years, you’re actually spending less. Factor in that energy efficient timber windows can match modern glazing for thermal performance, and the case gets stronger.

And then there’s what accountants call “intangible value”—the things that don’t show up on a spreadsheet. Character. Heritage. The satisfaction of opening a perfectly balanced sash every morning. These matter when you’re living with something every day. They definitely matter when you come to sell.

Handmade timber windows add character and prestige to your home in ways no mass-produced alternative can match. If you’re renovating a period property—whether it’s a Georgian townhouse in Kensington or a Victorian semi in Birmingham—the right windows don’t just complement the building; they complete it. They tell visitors you care about quality and authenticity. Buyers notice. And they pay for the difference.

There’s also the practical matter of replaceability. With bespoke windows, you’re not dependent on a manufacturer who might discontinue your window style next year. The designs are timeless, the construction methods proven. If you need a repair in twenty years, any skilled joiner can make it. Try finding replacement parts for a discontinued uPVC system from 2005.

The heritage aspect deserves special attention, particularly for UK homeowners. Many of our most beautiful buildings feature original timber windows that have stood for centuries. When we replace these with modern alternatives—however practical they might seem—we lose a piece of architectural history. Choosing handmade wooden windows for listed buildings or conservation areas isn’t just about meeting planning requirements; it’s about stewardship. You’re preserving character for future generations.

There’s something deeply satisfying about living with objects that have genuine quality. You notice it every time you open a perfectly balanced sash or appreciate the grain pattern in your window frames. These small moments of pleasure accumulate over years, adding up to a different relationship with your home. You’re not constantly dealing with failures and replacements—you’re simply enjoying something that works beautifully.

This is the ultimate luxury in our disposable age: products that don’t need to be replaced. That improve with age rather than deteriorate. That can be repaired rather than thrown away. Handmade timber windows embody this philosophy completely.

Choosing Handmade Timber Windows: Quality Craftsmanship That Endures

In a world where so much is designed for obsolescence, handmade wooden windows stand as a testament to enduring quality. They represent the best of both worlds: traditional craftsmanship perfected over centuries, combined with modern materials and precision manufacturing techniques.

The mortise and tenon joints, the carefully selected timber, the hand-applied microporous finish, the attention to every detail—these aren’t just technical specifications. They’re the visible expression of a philosophy that says some things are worth doing properly, even if they take longer and cost more initially.

When you choose handmade timber windows, you’re not just buying a building component. You’re investing in genuine craftsmanship, supporting traditional skills, and installing something with character and provenance. These windows will outlast trends, endure through decades of British weather, and potentially outlive the people who installed them.

The story of your home includes its windows. Every time you open them, close them, or simply look through them, you’re interacting with the craftsman’s work. Make sure it’s a story worth telling.

Ready to Invest in Windows That Last?

At Wooden Windows Online, we’ve been supplying handmade timber windows across the UK for over a decade. Every window is made to measure—from Georgian sash windows for a Kensington townhouse to casement windows for a Lake District cottage.

Our craftsmen understand that quality takes time. From selecting quarter-sawn oak to hand-finishing each frame, we don’t cut corners. We deliver nationwide, supply-only, which means you’re paying for craftsmanship—not showroom overheads.

Free consultation included. We’ll discuss your specific requirements, show you timber samples, and provide detailed quotes with no obligation.

Contact us today to discover why homeowners across London and beyond choose our timber windows for their properties.

FAQ

How much more expensive are handmade timber windows compared to mass-produced alternatives?

–

+

Handmade timber windows typically cost £800-1,200 per window compared to £400-600 for basic factory-made alternatives – roughly double the upfront cost. However, handmade windows last 60+ years with basic maintenance, whilst cheaper alternatives need replacing every 20 years. Over the window’s lifetime, handmade timber actually costs less per year of service whilst adding significantly more value to your property.

What makes a timber window truly ‘handmade’ in modern manufacturing?

–

+

Modern handmade windows combine traditional joinery skills with precision machinery. Craftsmen select timber individually, operate CNC equipment to cut joints to 0.2mm tolerances, hand-assemble using mortise and tenon joints, and personally inspect every stage. Unlike mass production where automation dominates, handmade means expert decisions at every step – the craftsman controls the machinery, not the other way around.

How long do handmade wooden windows last compared to uPVC or aluminium?

–

+

Properly made and maintained timber windows last 60-100+ years. Many Victorian and Georgian originals are still functioning after 150+ years. uPVC windows typically last 20-30 years before seals fail and frames discolour. Aluminium lasts 30-45 years but cannot be repaired. Crucially, timber windows can be maintained and repaired indefinitely, whilst synthetic alternatives must be completely replaced at end of life.

Are handmade timber windows suitable for modern energy efficiency standards?

–

+

Yes, absolutely. Modern handmade timber windows achieve U-values of 1.4 W/m²K or better, comfortably meeting Building Regulations Part L. With proper draught-proofing, double glazing, and precision manufacturing, timber windows match or exceed the thermal performance of uPVC whilst offering superior comfort due to wood’s natural insulating properties. The thermal mass of timber frames also helps moderate indoor temperatures.

What maintenance do handmade wooden windows require?

–

+

External surfaces typically need repainting every 6-10 years depending on exposure and paint quality. Internal surfaces rarely need attention beyond occasional cleaning. Annual checks of seals, hinges, and locks take 10-15 minutes per window. This modest maintenance schedule is manageable given the windows’ 60+ year lifespan. Quality microporous paint systems extend repainting intervals considerably.

Can handmade timber windows be used in listed buildings and conservation areas?

–

+

Yes, and they’re often the only acceptable option. Conservation officers typically require replacement windows to match original designs exactly – something only bespoke handmade windows can achieve. Factory-made windows lack the authentic details, profiles, and proportions of period originals. Handmade windows can replicate historical designs precisely whilst incorporating modern glazing and weather-sealing for improved performance.